High-speed osmosis pump laser drilling machine JGD-30

Time:2015-10-16 Times:2155

The basic structure of the osmotic pump controlled release tablet is: firstly, the drug is made into a core, and a semi-permeable membrane of a polymer material is wrapped, which is called a coating, and then a small hole is processed on the outer coating film, which is called Release hole. After oral administration of the drug, the gastrointestinal water passes through the semi-permeable membrane, so that the core dissolves into a saturated solution, producing an osmotic pressure of 40-50 atm, which forms a difference with the natural osmotic pressure of 7.5 atm of the human body, so the drug can be smoothly released. The pores flow slowly at a constant rate to form an accurate and convenient drug delivery system. This shows the importance of the release orifice, so the drilling process is a key process in the production of controlled release tablets. The processing of the release hole has mechanical punching, expansion, and laser drilling, but the laser drilling machine has obvious advantages from the comparison of the punching efficiency and effect. Therefore, this paper uses the special laser drilling machine developed in this paper to carry out in-depth experimental research on laser technology.

1. The particularity of the release hole of osmotic pump controlled release tablets

First, the concept of "dissolution" of an osmotic pump controlled release tablet is defined. The "dissolution" is the force used to completely dissolve the drug and completely release it from the coating. This medicine can be taken once a day, which greatly facilitates the administration of patients and has high drug safety and effectiveness. In view of the strict "time" requirements for the release of controlled release tablets, the release of drugs also has obvious specificities.

1. The pore size of the release hole must meet the dissolution requirements.

Different types of cores may have different dissolution rates, but the time of dissolution is controlled within 24 hours. The release orifice is the only channel for drug release, so the pore size of the release orifice directly affects the dissolution. That is, the pore volume is large, the flow rate is large, and the time for complete release of the drug is short. On the contrary, the time taken is long. Therefore, for different cores, the release aperture has a corresponding value, which satisfies the requirement of 24h dissolution.

2. The relationship between the dissolution rate of the drug and the hole shape of the drug release hole

The drug flow rate through the drug release orifice is determined by the pore area of the drug release orifice, that is, the larger the pore area, the shorter the time required for the complete release of the drug, and the shape of the pore is not related, so the adjustment of the dissolution degree is actually the orifice. Area control. In this experiment, a normal spherical laser focusing mirror is used, so the hole shape is circular, and the required aperture area can be obtained by controlling the size of the aperture.

3. Dissolution is independent of hole depth

Obviously, the rate of drug release is determined by the size of the orifice of the drug delivery orifice regardless of the pore depth. The depth of the hole is at least the thickness of the penetrating coating so as to form a passage through the coating. The depth of the hole deep into the core of the core will damage the core, but the loss is small, and the effect on dissolution is negligible. The depth of the experiment is designed to be about twice the thickness of the coating.

4, carbonization of the hole wall

The coating of the osmotic pump controlled release tablet is composed of a polymer organic material factory, which is easily carbonized by heat; the core of the tablet is composed of drugs and auxiliary materials, and the main component of the auxiliary material is sugar, which is also very sensitive to heat. Laser processing is precisely thermal processing, so the hole wall of the controlled release film is easily carbonized when punched. It takes tens of seconds to several minutes for the carbonized layer to be dissolved by water, and the effect on the overall dissolution is not significant. However, in order to avoid the adverse effects of the carbonized layer, measures need to be taken to reduce or eliminate the carbonized layer and make the tablets of high quality.

5, batch and fast drilling requirements

Osmotic pump controlled release tablets are a new formulation for the pharmaceutical industry and are particularly favored for their unique advantages. The newly developed controlled-release tablets, once put into production through approval, are generally large in volume and tight in construction period. Because manufacturers always hope to put them on the market as soon as possible, rapid laser drilling is an inevitable requirement. In response to this situation, laser drilling equipment is generally a fast-flowing production line that is automatically controlled. The stability of the punching process is very important in the face of dozens of punching speeds per second. In order to ensure the consistency of dissolution of all tablets, the shape of the hole (hole area), hole depth and other indicators should be strictly guaranteed, otherwise, a large number of bad pieces will be scrapped.

2. Experimental study on laser drilling of osmotic pump controlled release tablets

Different drugs, excipients and coating materials of different controlled release tablets have different compositions or different contents, so the difference in physical and chemical properties is large, which affects the process and effect of laser drilling. Scattered data can be used for reference, so laser drilling is a must for all new drugs developed. This is a basic work with a lot of work. It is very meaningful to build the relevant parameters of the accumulation into a database. For the development of new drugs, according to the composition and content, to query the relevant parameters in the library, to guide research or students, thereby reducing the need to repeat the relevant experiments, to save resources.

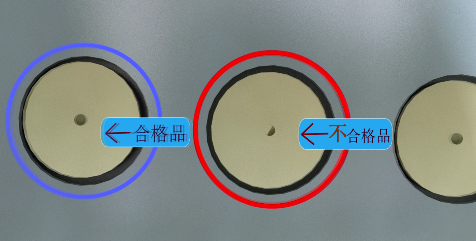

This experiment adopts a special laser drilling equipment for osmotic pump controlled release tablets developed by this project. The whole machine is the integration of light, machine and electric technology. It consists of cloth distribution system, transmission system, laser system, detection system and rejection system. composition. The laser is a sealed-off laser with a power of 40W and a beam diameter of 10mm. After laser power modulation and software control, the output of the laser becomes pulse output, and the pulse width is adjustable; the ZnSe lens with a focal length of 100mm is focused on the surface of the tablet; The controlled release tablets have a diameter of Ø8mm and a thickness of 4mm. The coating material is cellulose acetate and the thickness is 0.2mm. The high-quality camera and measuring microscope are used to detect the punching quality of the tablets, and the visual identification system and compressed air are used to identify the non-conforming products. And automated, automated laser drilling equipment that enables the production of large quantities of tablets.

Figure 1. Visual identification system detects processed tablets

The pore size is very sensitive to changes in the amount of defocus, ie the amount of defocus has the greatest effect on the pore size. The focal plane aperture is the smallest, and the aperture becomes rapidly larger as the defocus amount changes at other positions. Therefore, when the tablet is punched, the defocus amount is the preferred parameter for adjusting the aperture size.

The laser current (power) has a small effect on the aperture, and the aperture gradually increases as the current increases. Under the selected experimental parameters, the carbonization of the pore wall becomes more obvious with the increase of current, so the influence of current on the carbonized layer is large. Therefore, for the combination of the parameters of the punching process, the laser current should be selected in a small direction to reduce or eliminate the carbonization of the pore walls.

The laser pulse has the least influence on the aperture. Although the aperture increases with the increase of the pulse width, the trend is very gentle. Within the condition range of this experiment, as the pulse width becomes larger, the hole depth increases, so the drilling process parameters The combination of the pulse width should be selected in a small direction to ensure the damage of the core to the core.

The laser drilling method is used to process the release hole of the osmotic pump controlled release tablet, which has the advantages of high speed, high quality and obvious advantages, and the adjustment of the aperture is very convenient. Several major process parameters in the experiment played different roles in the formation of pores; the amount of defocus mainly affected the pore size; the laser current mainly affected the carbonization layer; the laser pulse mainly affected the pore depth. These phenomena and laws have a guiding or reference role in improving the efficiency and quality of osmotic pump controlled release laser drilling, which is very meaningful for the development of China's osmotic pump controlled release sheet industry.

Figure 2. Second-generation laser drilling machine research completed